Industries

Water Treatment Plant

"Advanced technology and expert management for efficient water treatment processes."

Advanced control software is used for predictive maintenance, analyzing performance trends, and ensuring compliance with safety and regulatory standards.

Flow meters, pH sensors, turbidity sensors, and pressure transmitters are used to monitor various water quality parameters.

Operators are responsible for monitoring the SCADA system, ensuring the correct chemical dosages, and troubleshooting any alarms or issues.

Desalination Plant Automation

Energy management software helps to optimize energy consumption, as desalination can be energy-intensive.

RO units are often automated to control the pressure and flow rate during desalination.

Engineers focus on troubleshooting, preventive maintenance, and optimizing the system for efficiency.

Ash Handling

This helps forecast potential equipment failures based on operational data, minimizing downtime.

Automated to transport ash continuously from the boiler to the ash silo or disposal area.

Operators monitor the systems, check ash levels, and ensure smooth operation.

Capacitor Panel

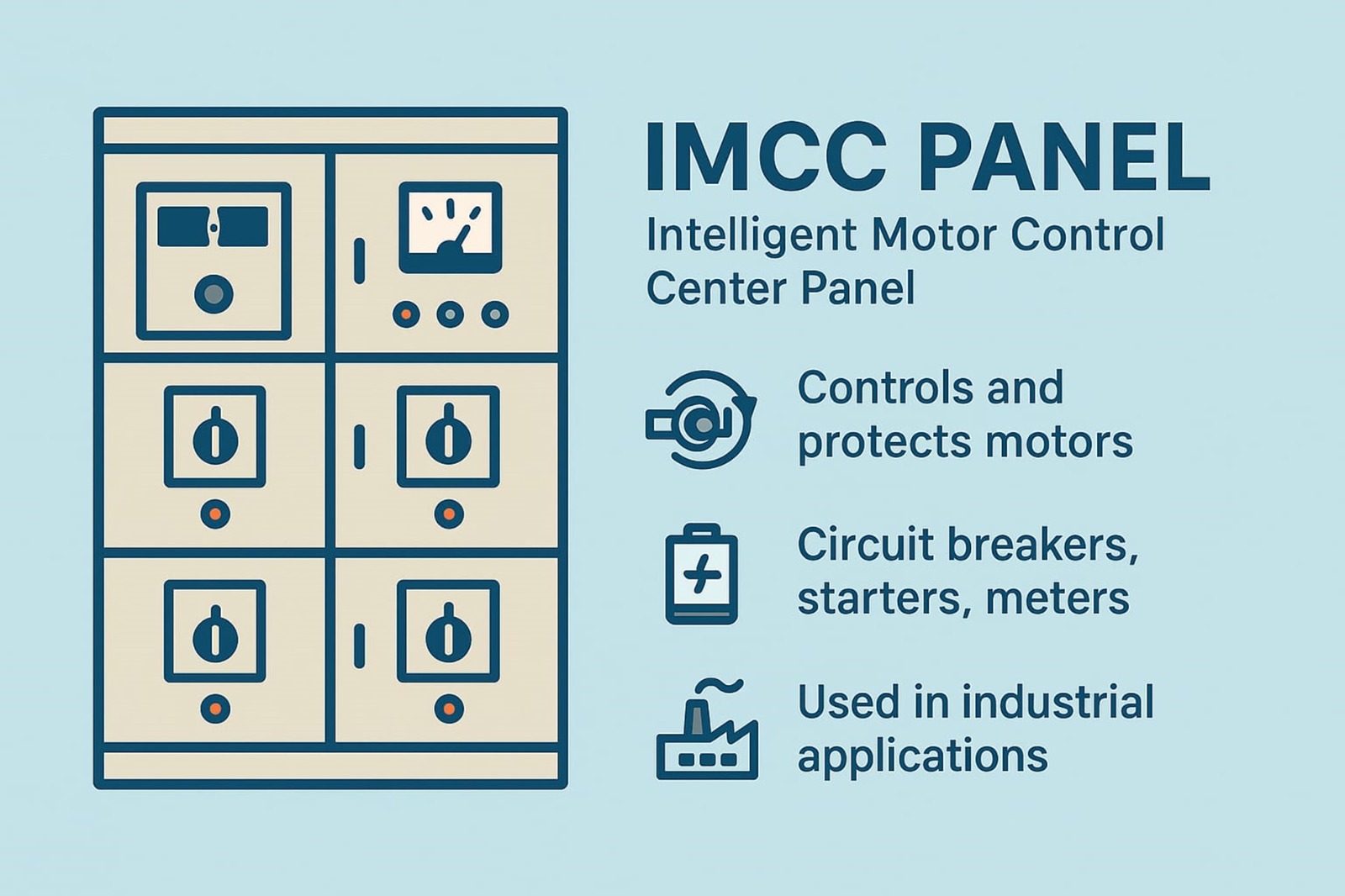

Software that manages motor start/stop sequences, overload protection, and fault diagnostics for IMCC systems.

These are used to improve the power factor by compensating for reactive power.

Electricians and control room operators are involved in monitoring the status of IMCCs and capacitor panels.

Boiler Automation

These systems collect data from sensors throughout the boiler and allow operators to monitor performance, alarms, and alerts.

Controls and optimizes the combustion process.

Operators are responsible for overseeing the control systems, responding to alarms, and ensuring safe and efficient operation.